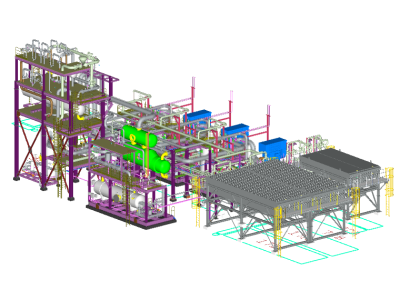

At ISS, we specialise in ensuring the purity and safety of natural gas through our expertise in amine sweetening. We are capable of providing effective solutions covering both adsorbtion and regeneration systems. This process is essential for removing hydrogen sulphide (H₂S) and carbon dioxide (CO₂) from gas streams, preventing corrosion and meeting stringent environmental and safety standards. Our advanced amine sweetening systems are designed to efficiently absorb these contaminants, allowing for the continuous production of clean, marketable natural gas. By optimising the regeneration of the amine solution, we ensure a sustainable and cost-effective operation.

Sulphur Removal Efficiency: Achieves high sulphur removal efficiency, reducing H₂S and CO₂ content to pipeline specifications (down to 4 ppm H₂S).

Flow Rates: Capable of processing gas flow rates from 1 to 200 MMSCFD, and is customisable to project requirements, accommodating a wide range of operational needs.

Amine Circulation Rate: Customisable circulation rates, ensuring optimal contact time and enhanced gas sweetening performance.

Regeneration Efficiency: Regenerates up to 99% of amine solution, reducing chemical costs and ensuring sustainable operations.

© 2024 ISSPROCESS. All Rights Reserved.